Introduction:

Timber cladding is a popular choice for both residential and commercial buildings, offering a natural and aesthetically pleasing exterior. To enhance the durability and longevity of factory-coated timber cladding, one often overlooked but crucial element is the application of an end grain sealer. In this blog post, we will explore the significance of end grain sealer and the potential side effects of neglecting this important step.

Understanding Factory Coated Timber Cladding:

Factory-coated timber cladding is designed to withstand environmental elements and provide a protective layer against moisture, UV rays, and other external factors. However, the ends of timber boards, known as the end grain, are particularly vulnerable to moisture absorption, leading to potential issues such as warping, splitting, decay and premature coating failure.

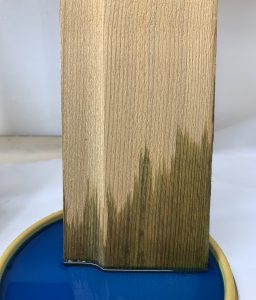

This image is an example of factory coated timber cladding that has been installed without end grain sealer. Moisture is traveling up the end grain of the timber which in turn is causing coating degradation.

The Role of End Grain Sealer:

End grain sealer is specifically formulated to address the vulnerability of timber cladding at its exposed ends. It creates a protective barrier that prevents moisture from penetrating the end grain, reducing the risk of water-related damage.

Possible Side Effects of Neglecting End Grain Sealer:

Moisture Absorption and Swelling:

- Without proper sealing, the end grain acts like a sponge, absorbing moisture and leading to swelling of the timber. This can result in an uneven appearance and compromise the integrity of the cladding over time.

Warping and Cupping:

- Unsealed end grains are prone to warping and cupping as it absorbs moisture unevenly. This distortion not only affects the visual appeal of the cladding but can also compromise the overall stability of the board.

Increased Risk of Decay:

- Moisture-laden end grain becomes a breeding ground for fungi and bacteria, increasing the risk of decay. This not only compromises the appearance of the cladding and coating system but can also jeopardize the integrity of the facade.

Reduced Longevity:

- The absence of end grain sealer accelerates the degradation of the coating, reducing its overall lifespan. More frequent maintenance and repairs may become necessary sooner than expected, leading to increased costs over time.

Here we have uncoated Western Red Cedar sat in a mixture of water and blue food colouring to demonstrate how moisture travels up the end grain of timber.

The image above is factory coated Larch that has been installed vertically without end grain sealer and is showing signs of moisture ingress through the end grain which is beginning to cause coating system failure.

Conclusion:

In conclusion, the application of end grain sealer on factory-coated timber cladding is not just a recommended step; it is a crucial component in preserving the integrity and aesthetics of the coating system. By taking proactive measures to protect the vulnerable end grain, property owners can ensure that their investment in coated timber cladding stands the test of time, remaining both visually appealing and structurally sound for years to come.

All coating manufacturers offer an end grain sealer as part of their system specification, which are all available at the time of ordering your coated timber cladding. For more information or application instructions, please get in touch.